Light weight running at 170 strokes per minute

Dust free, low noise, easy to maintain, can be built in 2 weeks at 30% cost

Quality built tools made to run...

Horizontal or VTS...

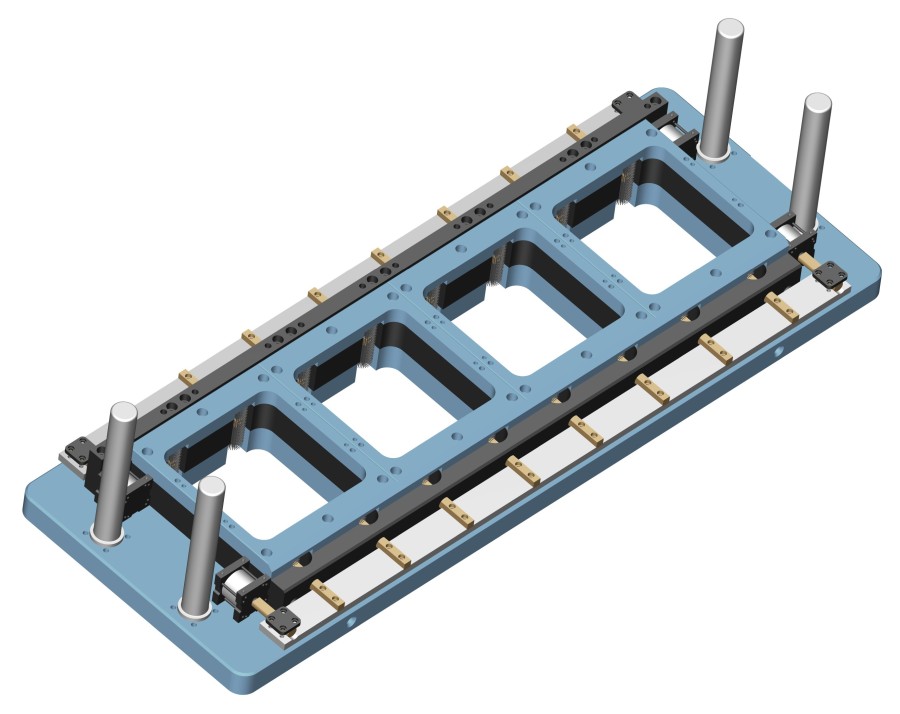

We build standard match metal punch and die trim tools for horizontal and vertical machines. We can build them with pre-punch stations, perforations, hole puncture and label placement mechanism. Aluminum or steel shoes. Hardened A2 D2 (Rc58-62) punch and die and soft peen-able dies with hard punch.

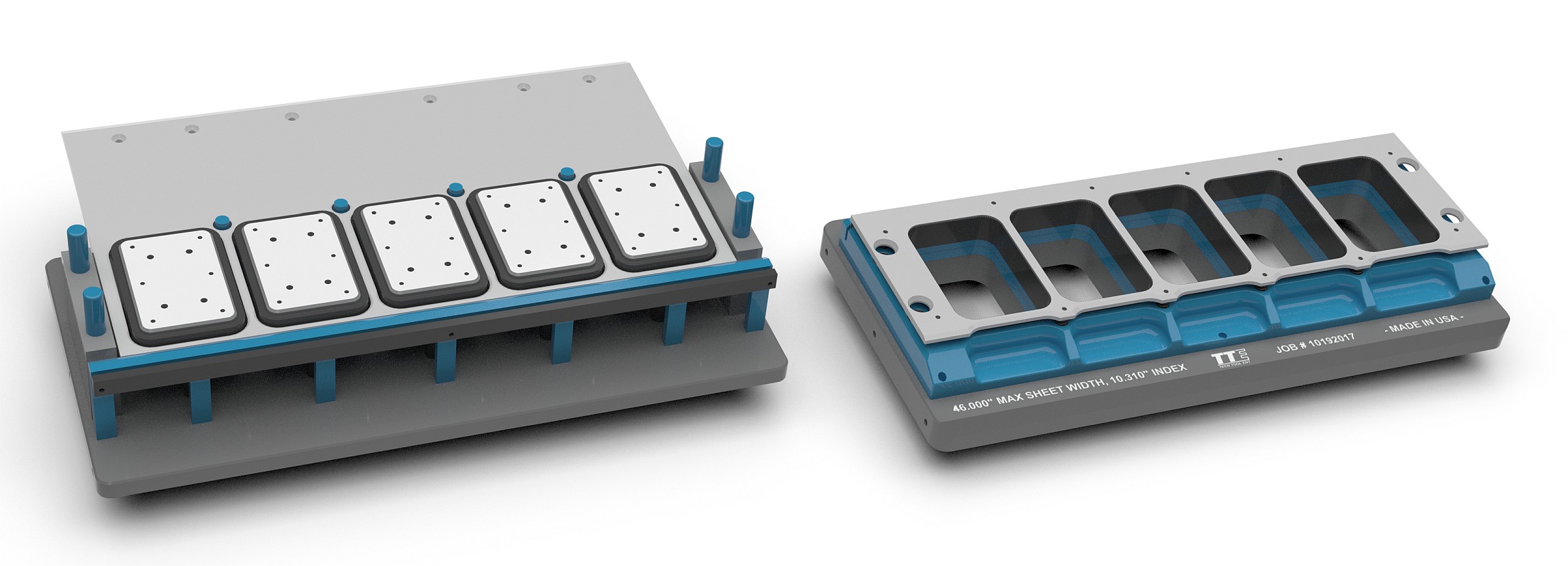

Click on image to enlarge

4up VTS aluminum shoe trim tool with A2 Punch and Die (Rc 58-60) and actuated brushes to hold part stack.

Cut PS Foam faster...

At Tech Tool, we have perfected serrated knife pass through trim tool design for PS foam. These tools are light weight, built using aluminum and plastic, run as fast as the trim press will allow it, run quiet, run with 0.020 blade/punch clearance, do not require running guide pins (only for setup), last 18 months with $40 blade, eliminate dust and can be built for under $10,000 in 2 weeks time.

Steel rule dies...

We can also build standard steel rule trim station for formers such as: Sencorp, Kiefel, Illig, Inpak Makina with up or down stacking station. Options include: perforation station, heated knifes, floating knifes, serrated knifes mixed with cutting knifes, cushion plates, spring loaded cone guides, A-B de-naster pneumatic rotational stacker, part counter.

Tech Tool Enterprise 100 Monaco Drive Roselle IL 60172 (630) 893-3428 sales@techtoolent.com